Battery cells made by Accelera by Cummins are on display at Cummins Engine Plant in Columbus, Ind., Thursday, July 11, 2024. The Department of Energy announced they’ve awarded Cummins a $75 million grant to convert some of the manufacturing space at the plant to produce zero-emissions components and electric powertrain systems. Mike Wolanin | The Republic

Cummins Inc. has received a $75 million federal grant to be used to convert nearly half of Columbus Engine Plant (CEP) for the production of zero-emissions components and electric powertrain systems, the company announced Thursday.

The grant is the largest grant ever awarded to Cummins, the company said, and was paid for through appropriations related to 2022’s Inflation Reduction Act (IRA).

Representatives from Cummins, the city, county and state, along with U.S. Department of Energy Under Secretary for Infrastructure David Crane gathered together for the announcement on the CEP floor on Thursday afternoon.

Cummins is matching the grant, meaning a total of $150 million will go towards the conversion of the space, expanding production of battery packs, powertrain systems and other battery-electric vehicle (BEV) components for Accelera by Cummins.

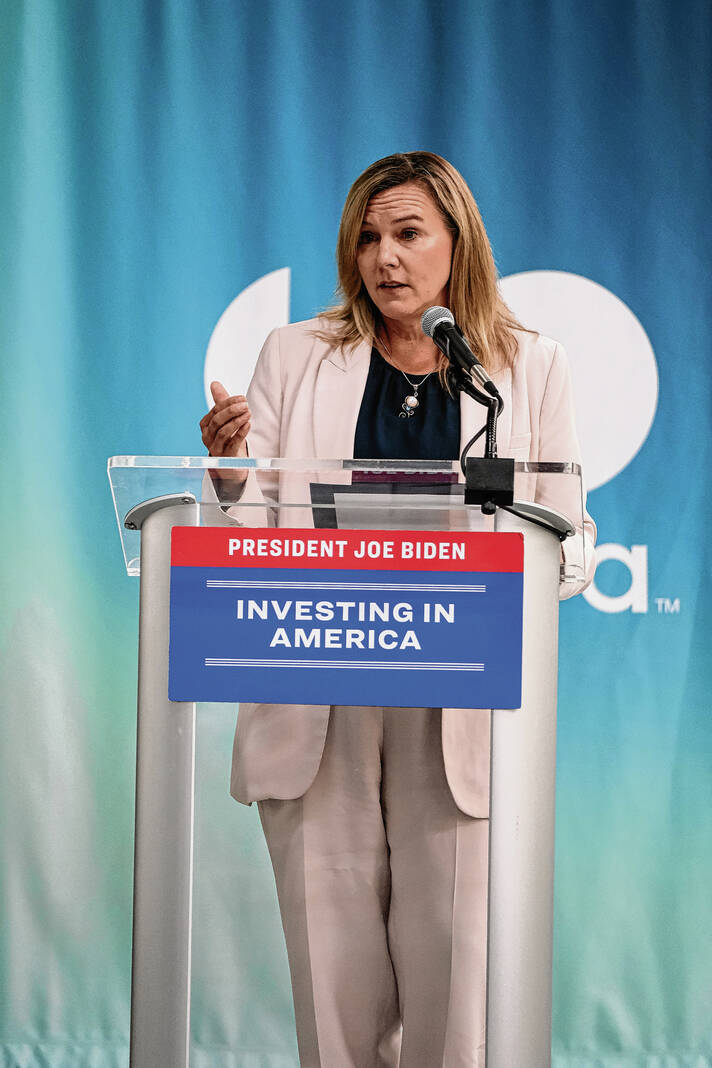

“This funding allows us to continue transitioning Accelera by Cummins for the future through expanded battery production right here at CEP,” said Amy Davis, president of Accelera by Cummins. “Once this project is complete, we’ll occupy approximately half of the 1.4 million square-foot plant, and we might just officially change the name of Columbus Engine Plant to the ‘Columbus Electrification Plant.’ “

The company rebranded the segment in 2023, seeking to secure its place in a world shifting away from the fossil fuels that Cummins engines have traditionally used.

Cummins officials said 350 employees focused on battery-electric vehicle work will occupy the space once the conversion is finished.

CEP currently produces 2,000 battery packs and 1,000 vehicle systems for electric vehicles per year, Davis said. Once the project is complete, Accelera will produce more than 84,000 battery packs and more than 22,000 vehicle systems for electric vehicles annually, according to Davis.

Helping that effort is a joint venture Cummins announced last month known as Amplify Cell Technologies, made up of Cummins, Daimler Trucks & Buses US Holdings and PACCAR, with a goal of localizing battery cell production and the battery supply chain in the United States. As part of the joint venture, the company also announced the construction of a 21-gigawatt hour (GWh) factory in Marshall County, Mississippi, which will begin production in 2027.

“It will also enable us to have industry leading battery packs that we’ll make right here,” Davis said. “By creating demand for electric vehicle components here in the US, we’re driving closer collaboration with domestic suppliers, ensuring a more resilient supply chain for electric vehicles and paving the way to a more sustainable future.”

As part of the grant, Cummins will also looks to expand investment in local robotics programs and STEM curriculum, including the construction of “new studios and labs for industry 4.0 experience within our community to prepare the workforce for tomorrow,” according to Davis.

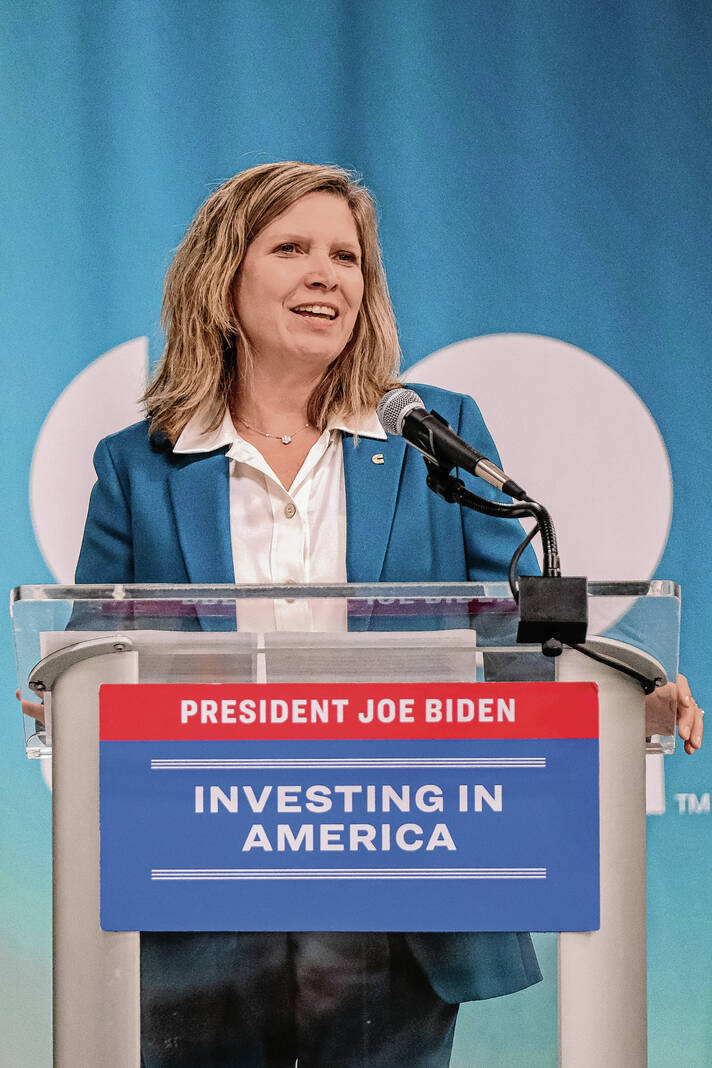

Jennifer Rumsey, chair and CEO of Cummins, said the grant is a chance for the company to “broaden the legacy” of the site of the company’s first engine plant, which opened in 1926.

“By expanding the production of batteries and electric vehicle components at CEP, at the same plant where we manufacture blocks and heads for our current and next-generation, engine-based solutions, we continue to prove our commitment to Destination Zero and dedication to innovation, strengthening the communities we serve and environmental stewardship,” Rumsey said. “As a Columbus native, I am especially proud of the significant contribution Cummins is making to economic and social vibrancies of the local community alongside our broader goals of improving and decarbonizing commercial and industrial applications.”

Destination Zero is the company’s previously announced goal of achieving zero emissions by 2050, including interim goals by 2030.

Cummins will add 250 full-time jobs at the facility due to the conversion, and there will be opportunities for the plant’s existing workforce to transition to the new positions over time, Cummins officials said. The electric powertrains produced at CEP will lead to greenhouse gas emission reduction of approximately 104 million metric tons of carbon dioxide by 2030, per the company.

“This expansion by Accelera reinforces the commitment the company has made to clean energy and a more sustainable future,” Columbus Mayor Mary Ferdon said. “Columbus also benefits from the re-investment in our workforce and the conversion of CEP space for advanced technology. We’re excited about this $150 million investment which moves the company forward in its zero-emissions manufacturing and de-carbonization goals and we’re proud to celebrate this milestone award from the Department of Energy.”

The $75 million Cummins received is part of a total of $1.7 billion in federal grants issued by the Energy Department for electric vehicle manufacturing and assembly sites at 11 locations in eight states including Michigan, Pennsylvania, Georgia, Ohio, Illinois, Indiana, Maryland and Virginia. Kokomo-based Stellantis, the parent company of Dodge, Ram and Jeep, received $250 million to convert a transmission plant to produce electric vehicle components.

Crane said applications for the manufacturing conversion award were “heavily contested.”

“What we were looking for was the relationship between management and the labor force and the community, we were looking for the tripod, as we call it,” Crane said, taking a moment to recognize representatives from the Diesel Workers Union (DWU) and Office Committee Union (OCU).

The $1.7 billion dispersed across the 11 sites will result in 2,900 high-quality jobs and will ensure the retention of 15,000 existing jobs, Crane said.

By Brad Davis, of The (Columbus) Republic, a sister newspaper to the Daily Journal.