Brett Barbee, right, vice president of business development for defense company Firestorm, talks about the Tempest 50 uncrewed autonomous system at the Technology Readiness Experimentation event Tuesday at Camp Atterbury in southern Johnson County. The event was part of a 10-day U.S. Department of Defense event to test and assess new defense technology, in partnership with Camp Atterbury and the Indiana National Guard. RYAN TRARES | DAILY JOURNAL

The future of the U.S. military might be found inside an isolated building in the far reaches of Camp Atterbury.

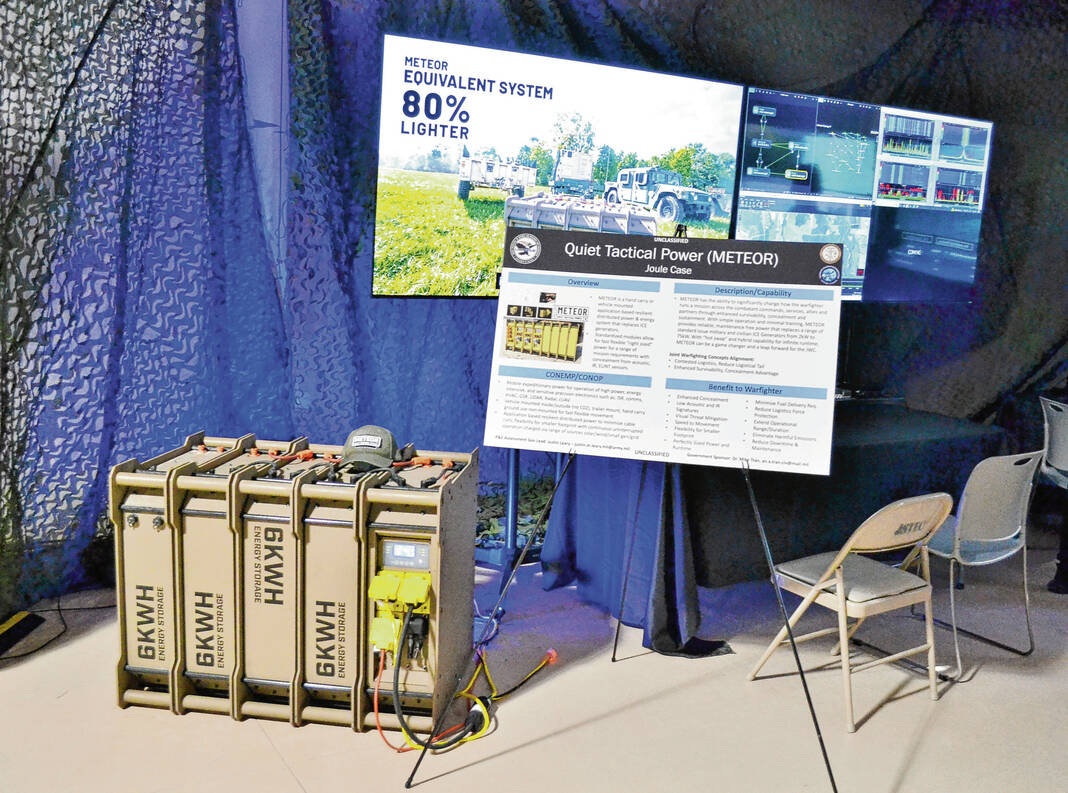

Displays showcased jet engines with no moving parts that could be mass-fabricated in a matter of days. Experts showcased munitions systems that attach to any drone, capable of dropping explosives in combat zones. Advanced wireless hubs and floating aerial surveillance make communication and coordination more secure.

None of the equipment featured at the military’s Technology Readiness Experimentation event was ready for use.

But the best advancements could soon keep U.S. military members — and the world — more safe.

“The quote I like to say is, we’re fighting today with tomorrow’s technology,” said Lt. Col. Matt Limeberry, task force Rapid Defense Experimentation Reserve commander for the Indiana National Guard. “These are doing things that you see in movies, and you think, this couldn’t be true. We’re proving in real life that it is true, and we’re well beyond where we ever thought we were.”

For 10 days, Camp Atterbury and the Indiana National Guard have played host to the event, known by the military as T-REX. Representatives from the U.S. Department of Defense met with defense companies to assess, test and learn more about the latest technology to be used in the theater of war.

Officials opened up the event on Tuesday, welcoming media representatives and leaders from around the country to see this year’s offerings. Nearly 80 different technologies were part of T-REX; though many would not be approved for military usage this time around, a number of approved weaponry could be in use as soon as 2025.

The dynamic turnaround is the goal of creating the T-REX program, said Marcia Holmes, principal deputy assistant secretary of defense for mission capabilities for the Department of Defense.

“Technology changes quickly. Threats change rapidly. Our traditional acquisition process just doesn’t often keep pace,” she said.

T-REX is a critical component of the Rapid Defense Experimentation Reserve, which facilitates modernization efforts through rapid prototyping and experimentation of integrated joint military technologies, according to the Department of Defense. Technology prototypes are used and assessed at T-REX events, requiring stringent validation before they are moved to field usage by the military.

In that way, T-REX provides a critical venue for accelerating joint innovation through real-world data — which can be used to inform the future warfighting concept development.

“Often, technologies are maturing down in the service labs, and they slowly make their way up the technology readiness scale. They’re waiting their turn, they’re waiting for available resources. Some might be established as a program of record, or incorporation into an existing program,” Holmes said. “But all too often, following the traditional acquisition process, some of them never transition at all.”

T-REX kicked off at Camp Atterbury on Aug. 19, with Indiana National Guard soldiers and other units conducting scenario-based training events using the equipment being tested.

Camp Atterbury and the Indiana National Guard have become important partners in presenting T-REX. The facilities and range space at the base, as well as the wealth of military personnel capable of testing the emerging technology, makes the partnership ideal for all sides, Holmes said.

“Soldiers already here on training can operate and evaluate the technologies under assessment,” she said. “Soldier-centered design — their user experience is another influential factor in the ability to accelerate prototype development.”

For the National Guard, participating in T-REX is a testament to the “art of saying yes,” said Brig. Gen. Justin Mann, director of the joint staff for the Indiana National Guard.

“So much time is spent on why you can’t do something, or the red tape. What we strive to do in the Indiana (National) Guard with the customers we support in the (Department of Defense) and academia is ask, how do we get to ‘yes?’ How can we accomplish that and help you because they’re also benefit for us with our soldiers who get to participate,” he said.

During Tuesday’s open house event, company representatives explained the different technologies they had developed. Tabletop displays showcased innovations in unmanned aircraft that could counter attacks by small enemy drones.

Companies described new systems of integrated base defense, designed to keep U.S. military bases safe from outside threats. Other presentations focused on providing the military with secure communications networks.

“This is our platform and campaign of events to accelerate the innovation and modernization of future warfighting capabilities,” Limeberry said. “We’ve taken 40 industry partners and their technologies, and validated their capabilities and technical validity for future acquisition into the (Department of Defense.)”

Brett Barbee, vice president of business development for defense company Firestorm, was in attendance informing people about the company’s Tempest 50 uncrewed autonomous system. The small aircraft, which weighs less than 55 pounds, is entirely 3-D printed in a matter of hours. They can then have a fully operational platform in 36 hours.

“Because we 3-D print, we can go faster than other competitors, who take six to eight weeks just to make one,” Barbee said. “We can make many in a matter of days. In terms of meeting the needs of the nation, we really feel like we have an opportunity to do that.”

Nearby, Andrew Geltman stood next to a sleek, tubular stainless steel piece of equipment — the J-1 Wave Engine. The jet engine is constructed by North American Wave Engine Corp., and is fabricated to have no moving parts; instead, it is filled with a shot of compressed air, fuel is injected into the combustion chamber and a spark plug ignites the fuel-air mixture.

The result is a vacuum, and as the cycle repeats itself, the aircraft is propelled forward. A jet engine without moving parts is beneficial because of it can be easily and quickly manufactured at a lower cost without sacrificing performance, Geltman said.

Showcasing the J-1 at Camp Atterbury had been a positive experience for the company, he said.

“T-REX is definitely a unique opportunity for a small company like us to get our technology in front of the (Department of Defense), and coordinate it with other technologies,” he said. “We’re really happy to participate.”